JD Ceramics: Exhibiting all kinds of ceramic nozzle solutions

Oct 23, 2025 | by

JD Ceramics has been specializing in the field of air interlacing jets, air texturizing jets, and water jets over 29 years. With several years of technical accumulation and continuous equipment upgrades, we have been consistently delivering high-precision, high-quality, cost-effective ceramic nozzle solutions to the market.

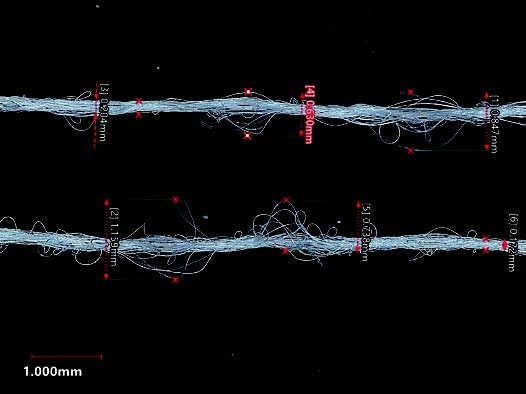

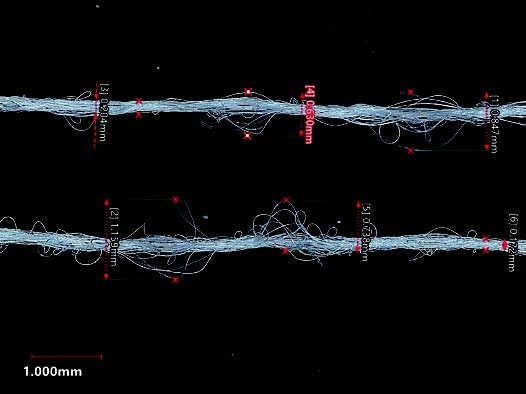

DTY-JDE 141 4N

Finer and more sensitive fibers, such as nylon, demand a superior surface quality from the jet. The JDE-141 is engineered with 99.99% high-purity alumina, which significantly reduces the friction in the yarn path. This effectively prevents the formation of excessive broken filaments during production. This material can be applied to any DTY nozzle model to meet specific requirements.

DTY-ES

The ES (Extra Saving) series of interlacing jets has been met with enthusiastic acclaim from the market over the past year. Particularly in the composite yarn application, the ES series can achieve energy savings of up to 20%, while at the same time, the quality of the interlacing knots has seen significant improvement.

ATY-KB

The KB series air texturizing jets are the latest solution that our company has provided in the field of air-textured yarn in recent years. These nozzles have a very compact design, weighing only 150g. Thanks to our high-precision manufacturing capabilities, the KB series outperforms traditional bulky air-jet nozzles with enhanced performance. The stability of the knots has significantly improved, and they can adapt higher winding speed.

Solution

JD Ceramics provide comprehensive solutions rather than standalone products, with service as an integral component of our offering. Their services include rapid yarn sample prototyping, supported by solid testing results. Furthermore, customers are welcomed to utilize JD Ceramics’s Barmag-EFK and Aiki machines to experiment with new concepts at any time. JD Ceramics is equipped to help customers respond swiftly to market changes and explore the full potential of new applications.