YOANTION: Pioneering advanced dyeing & finishing solutions

Oct 23, 2025 | by

Yoantion Industrial INC., LTD. is a listed company Stock Code 301053 specializing in high-end dyeing and finishing equipment. It serves as the vice president unit of the China Textile Machinery Association and the vice president unit of the China Dyeing and Printing Association. The company has been awarded numerous honors including National High-tech Enterprise and National Stenter Development Base. Its leading products are well-received both domestically and internationally.

Hot Air Stenter

The stenter adopts a brand-new design concept, suitable for the finishing, dewatering, and setting of knitted cotton, rayon, woven fabrics, and stretch woven fabrics. Equipped with visual sensing technology, it enables features such as empty trolley alerts, fabric centering, real-time clap detection, and setting requirements of any width. The exhaust system utilizes an independent dual-air-duct technology, enhancing energy efficiency.

Heat Recovery and Oil Fume Treatment System

The new integrated design of heat energy recovery and fume purification realizes the integration of heat energy reuse and fume purification of the stenter, saving about 20% of direct energy consumption, and the fume purification result is far better than the national standard. Intelligent MES operating system can remotely monitor the realtime process parameters of the stenter and the all-in-one machine.

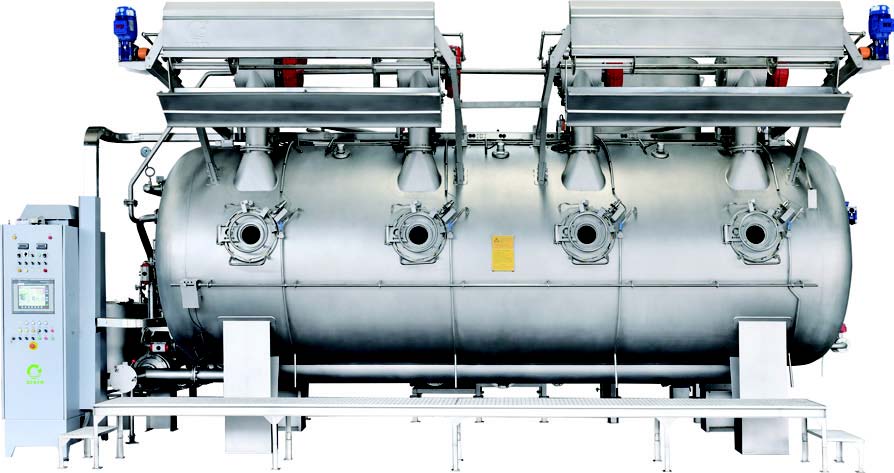

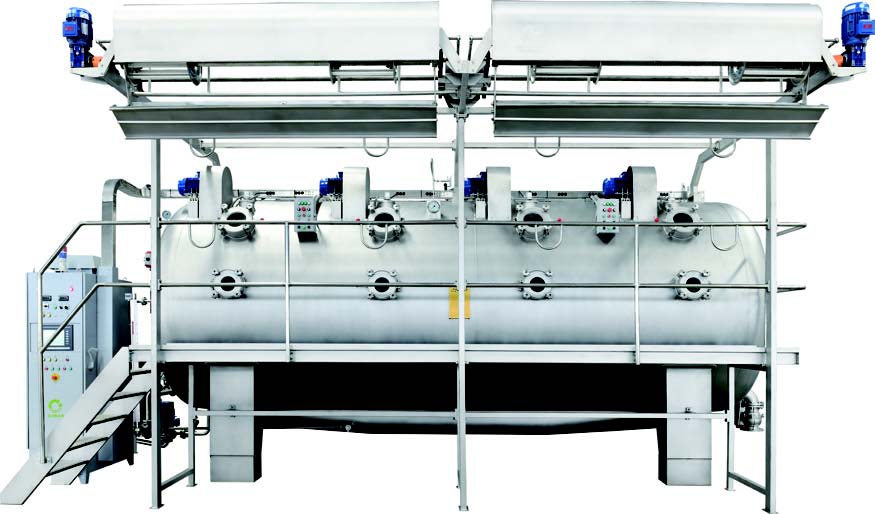

Dyeing machines

The ZJBSN-RE features a built-in fabric lifting wheel design with a cylinder diameter of 2,400mm and a loading capacity of 350- 500kg per tube, making it suitable for all types of cotton and blended knitted fabrics. It is equipped with a high-lift pump capable of achieving maximum nozzle pressure of 1.5-1.8Bar, an adjustable fabric channel to accommodate different loads, and a uniquely designed jet mixing system. The machine also includes a horizontal cloth oscillating device, Huagao computer control, water inflow flow meter, and proportional temperature control for heating and cooling.

The ZJBSN-OE adopts a traditional external fabric lifting wheel design with a loading capacity of 250-350kg per tube, suitable for various cotton and blended fabrics. It features an automatically adjustable gap nozzle for more stable fabric characteristics, along with a horizontal circulation mixing and uniform distribution system that enables rapid dye liquor-fabric exchange to ensure level dyeing and reproducibility. The machine comes standard with a German SEDO controller, Danfoss frequency converter, and UK Spirax Sarco steam trap, making it particularly suitable for producing various high-end fabrics.