Changshu Textile Machinery:Focusing on the shedding devices R&D for more than 60 years

Oct 17, 2025 | by

Changshu Textile Machinery Works Co., Ltd. was founded in 1958 and is a professional R&D and manufacturing enterprise of looms shedding device in China. The company's products cover three series of shedding devices for looms (Dobby, Jacquard, Cam Motion), forming a series of products with electronic shedding devices as the main products, and mechanical shedding devices as the auxiliary products.

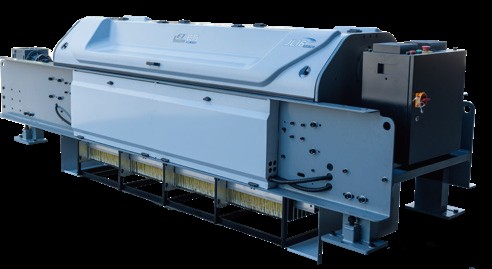

D2876pro electronic dobby

The D2876pro electronic dobby is a high-performance equipment designed for a maximum operating speed of 800rpm. It has 16 cams, and 12mm of pitch, with a high installation type. The shedding type is double lift and full clear open. Its maximum wefts is 12,800 and 100,000. It has a two-stage filtration lubrication with a gerotor pump oil recycle system, and it is suitable for water-jet looms.

D2875pro electronic dobby

The D2875pro electronic dobby is a equipment designed for a maximum operating speed of 750rpm. It has 16 cams, and 12mm of pitch. The shedding type is double lift and full clear open. Its maximum wefts is 12,800 and 100,000. It has a two-stage filtration lubrication with a gerotor pump oil recycle system, electronic pattern controlling, and it is suitable for water-jet looms.

Changfang JL series electronic jacquard

JL1630 electronic jacquard and the JL3220 electronic jacquard both feature a double-acting full-clear shedding form, a motion mechanism driven by a concentric shaft of a conjugate cam, and are compatible with the CFJC220, CFJC320, or CFJC380 controllers. They share a standard 4GB storage capacity, expandable up to 32GB, and are equipped with a side-mounted air-cooling system.

The key differences lie in their capacity and physical size. The JL1630 model accommodates 1408 to 6144 hooks and has a longitudinal module of 16 rows, with an outline size of 950 mm (W) x 1170 mm (H). In contrast, the JL3220 is a larger-scale machine, supporting 8448 to 20480 hooks with a 32-row longitudinal module, and its dimensions are 1610 mm (W) x 1250 mm (H).

S1671 Cam shedding device

The S1671 cam shedding device is equipment designed for a low installation position. It can hold 4 to 10 cams with a 12 mm pitch and features an automatic separation method. Its shedding type is a positive conjugate cam. It uses active gear pump lubrication. The pattern repeats every four to eight wefts, and it is suitable for water-jet looms.

CFC2 Shaftless service motor system

Direct drive motor is with low speed, large torque output characteristics, compared with servo motor, there is no need for deceleration mechanism, greatly reducing the failure rate. Replace the traditional vertical shaft transmission mode, simple and beautiful, green and energy-saving. Flexible start and stop, reduce the mechanical impact on the jacquard machine, so as to prolong the service life. According to the organizational characteristics of the pattern, the motion curve is optimized, so the operation is more smoothly. According to the process requirements of the fabric, the angular position of the shedding can be easily adjusted. The jacquard machine operates independently and has no additional requirements on the motor power of the loom.