GERON:Providing state-of-the-art carding equipment solutions

Oct 16, 2025 | by

GERON Card Clothing (Jiangsu) Co., Ltd. was founded in 1987 and is a professional textile carding equipment enterprise integrating research, production and sales. The production and sales of carding equipment have been leading the industry for many years. Our products include metallic card clothing, flat-top, stationary flat, circular comb and combing roller. Our brands include TYRION, Blue Diamond, Diamond, Pioneer and Lance. We provide customers with the most advanced carding solutions.

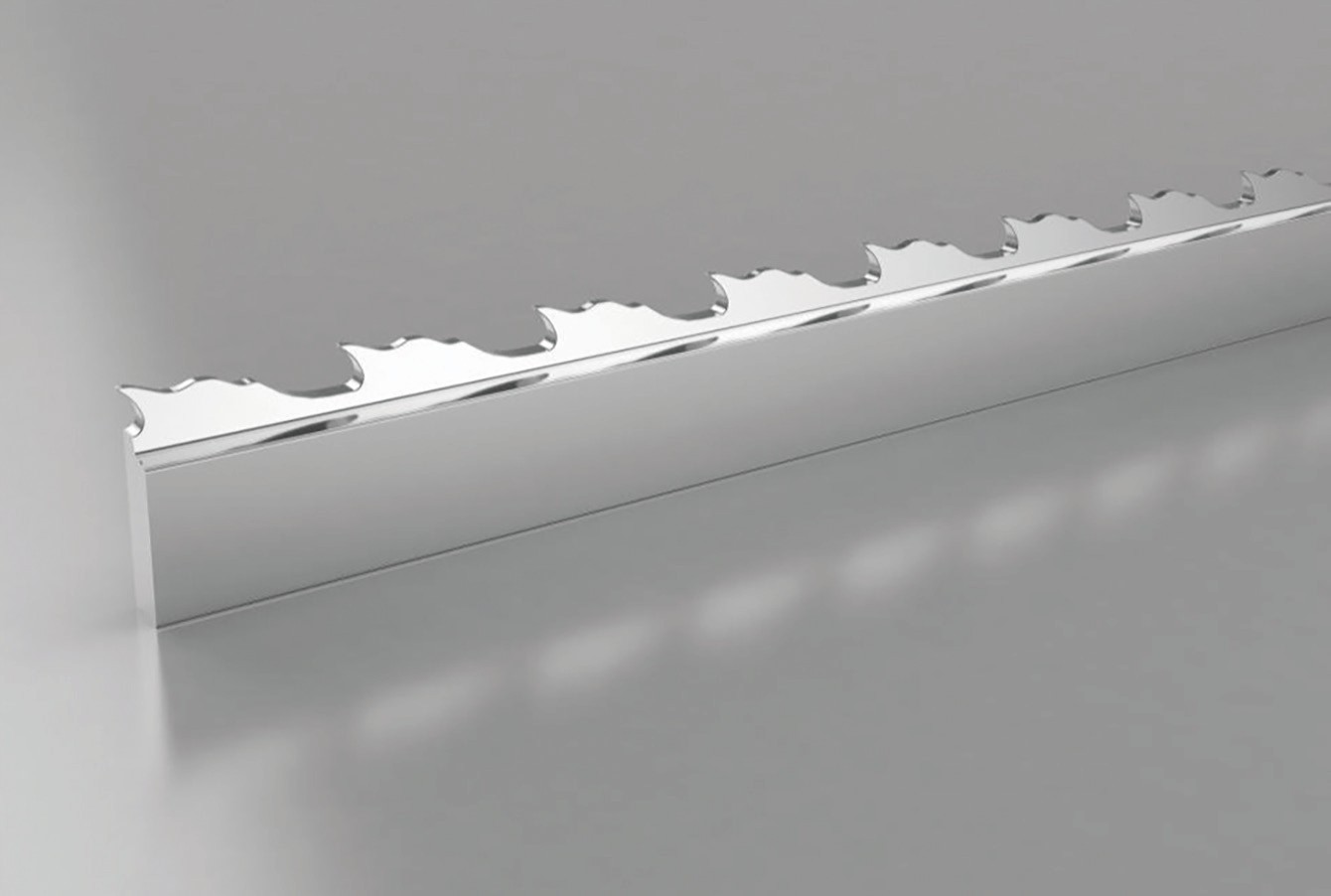

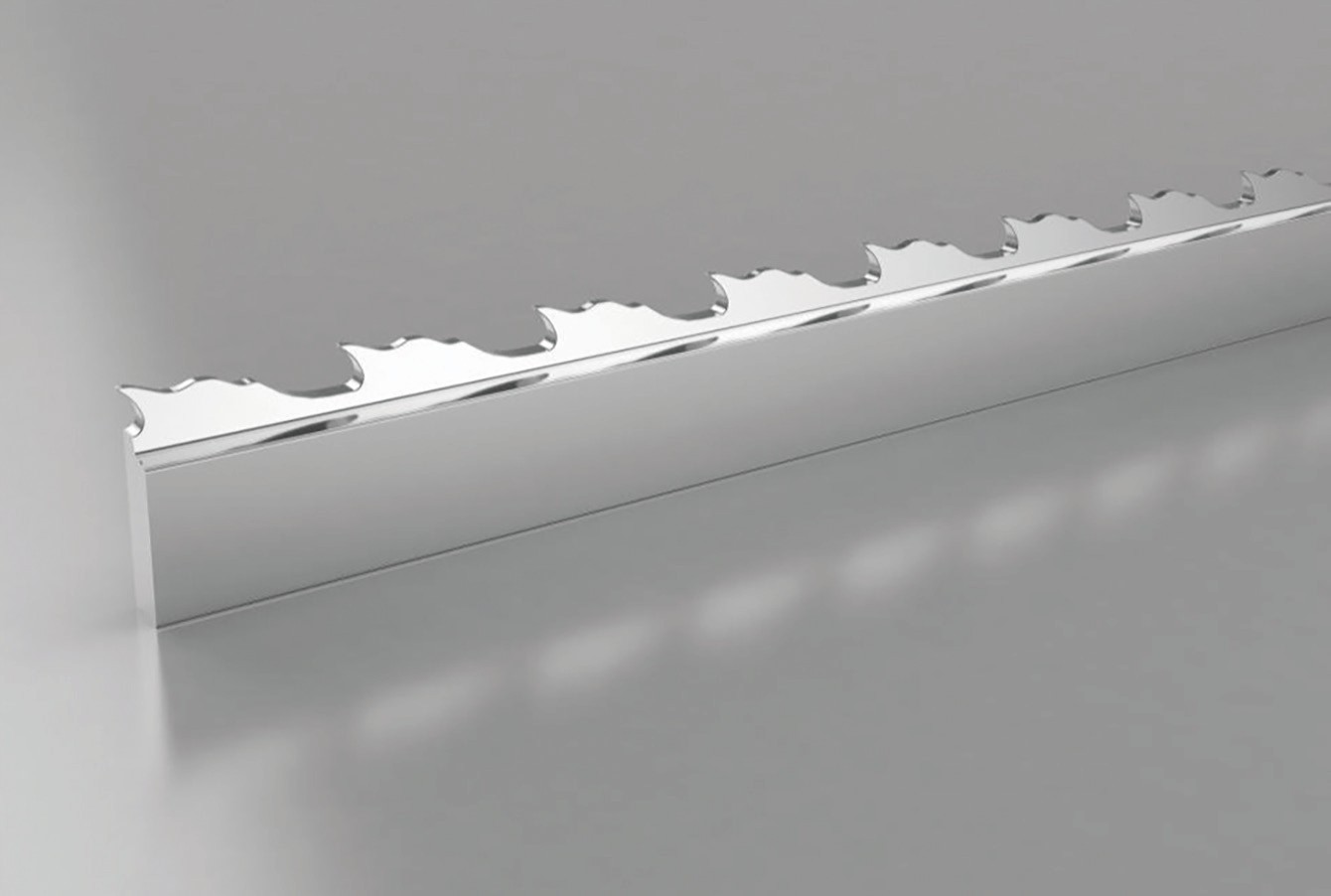

Cylinder wire-cotton

The high-production cylinder wire(A0-50-1080S-Ti) delivers enhanced fiber control its 50°working angle combined with the curved tooth design, improving the yarn yield. The optimized tooth design and arrangement ensure effective one time carding and sufficient fiber capacity, while plasma polishing and composite coating minimize fiber damage and short fiber generation. Treated with a hard alloy coating for high wear resistance, it offers a 30% longer lifespan than conventional wires. Ideal for ring spinning of 100% cotton below 60s (trash content<2.5%) and high-speed production ≥70 kg/h.

Cylinder wire for blended fibers

This cylinder wire for blended fibers (B2-35-896-Ti) provides high penetration and optimal fiber grip with its 35° working angle and sharp tooth design. Its high tooth density (896 teeth per square inch) ensures intensive carding, while the composite coating prevents fiber wrapping. Plasma polishing and the hard alloy coating minimize fiber damage and extend service life by over 30%. Ideal for vortex spinning of cellulose, polyester, and viscose-polyester blends at production rates ≥50 kg/h.

Cylinder wire for cellulose fibers

This cylinder wire (A2-45-1008-Ti) delivers a balance of fiber penetration and airflow lift with its 45° working angle and unique tooth profile design. The high tooth density (1008 PPSI) ensures intensive carding, while the composite coating prevents fiber wrapping. Combined with plasma polishing and a hard alloy coating for reduced fiber damage and over 30% longer service life, it is ideal for vortex and ring spinning of cotton, cellulose fibers, polyester, and their blends, across a wide range of yarn counts and production rates.

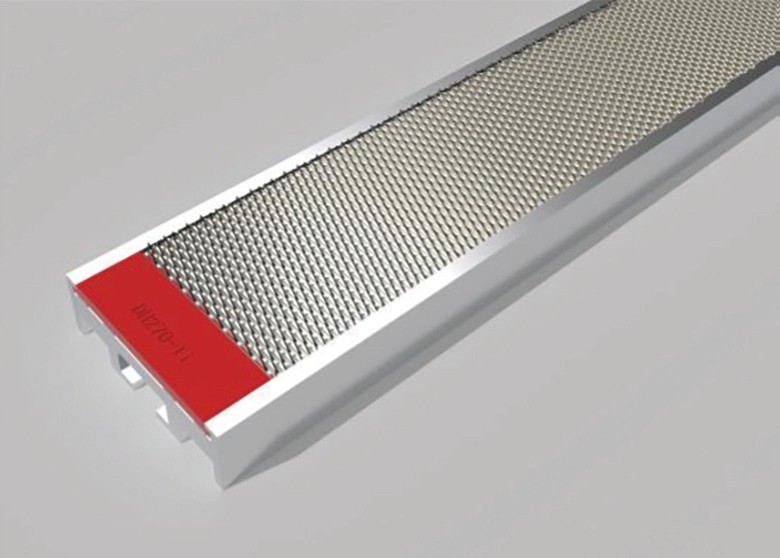

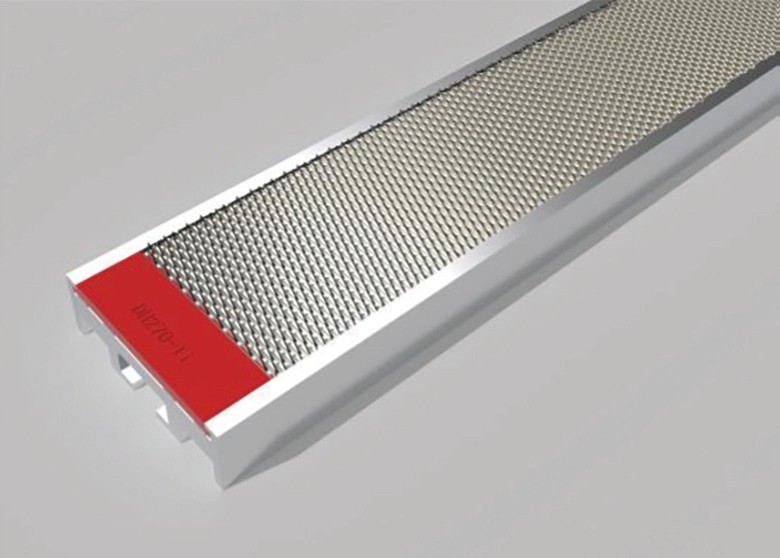

Cotton flat top

The 100% cotton flat top (BH-580) has a high-strength base fabric with enhanced elasticity and toughness. Its progressive arrangement optimizes the distribution of carding channels, ensuring more effective removal of short fibers and impurities while improving fiber carding and transfer efficiency, thereby enhancing flat cleanliness.

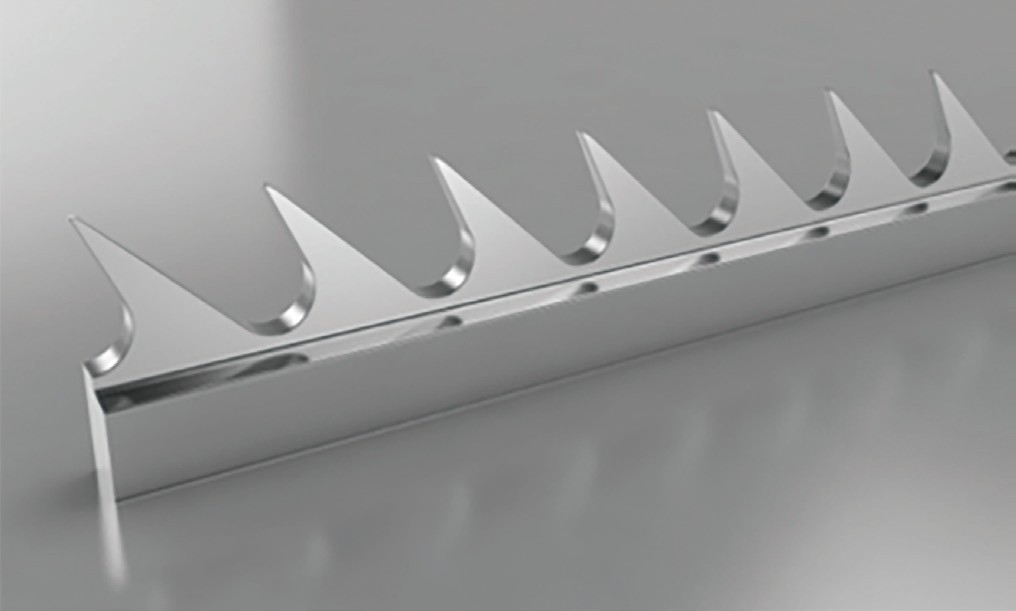

Interlock licker-in wire

This Interlock licker-in wire for cotton (AT5020S×05020V) offers high penetration and improved opening efficiency, with a 15-20% gain in capacity and a 10% reduction in short fibers due to its optimized working angle and hump-backed design. It promotes stable airflow and enhances trash extraction by 15-20%, lowering waste and overall costs. Ideal for cotton processing where high throughput and gentle fiber treatment are essential.

TYRION Stationary flat

Through the new generation of tooth profile structure design, TYRION Stationary flat further enhances the carding effect. Use special Ti coating, bring super longer life time. Compare high-carbon steel, life time improve 50%. The increased density of the front Stationary flat, particularly in the lateral direction, enhances fiber carding efficiency and reduces the occurrence of uncombed fibers. This improvement results in better straightness and parallel alignment, which contributes to more effective lint removal and significantly enhances yarn quality metrics. It serves as an optimal solution for mills to meet high-quality market demands.

Flat top bar for carding machine

The new high-strength flat top bar features a redesigned external profile and wall thickness structure through simulation-based calculations. This enhancement increases lateral bending resistance to suppress resonance, shifting the natural frequency away from the excitation source frequency. It improves stiffness in the vibration direction, thereby reducing vibration amplitude and thermal deformation. The application of advanced materials further boosts its anti-deformation capability. Compared to industry-standard bar, the optimized new high-strength flat top bar exhibits 0.03mm to 0.05mm less deformation during actual machine operation tracking than existing bar structures.

OE Wire

OE wire greatly enhances carding performance, this is because that the sharpness of the tooth tips is further improved to enhance fiber penetration capability and carding efficiency. The rounded cutting edges of the tooth tips minimize fiber damage, and its thickened coating extends the life time of the card clothing. The product effectively improves yield rate, enhances yarn strength, and reduces hairiness.

Apart from the above products, the company will also exhibit double-tooth card clothing for 100% cotton, flat top for vortex, and non-woven card clothing, etc.