Jingwei Textile Machinery: Realization of full integration of logistics, process flow and information flow in spinning mills

Nov 15, 2024 | by Zhong Mengxia

Jingwei has focused on intelligent manufacturing as its primary direction after the Three-year Action towards scientific and technological innovation and revitalization of textile machinery. This has allowed Jingwei to strengthen advantages and supplement disadvantages. Through technologies of automation, informatization, digitalization, and intelligence, an entire process of intelligent equipment, logistics system, and management system are developed, providing comprehensive integration of logistics, process flow, and information flow in spinning production.

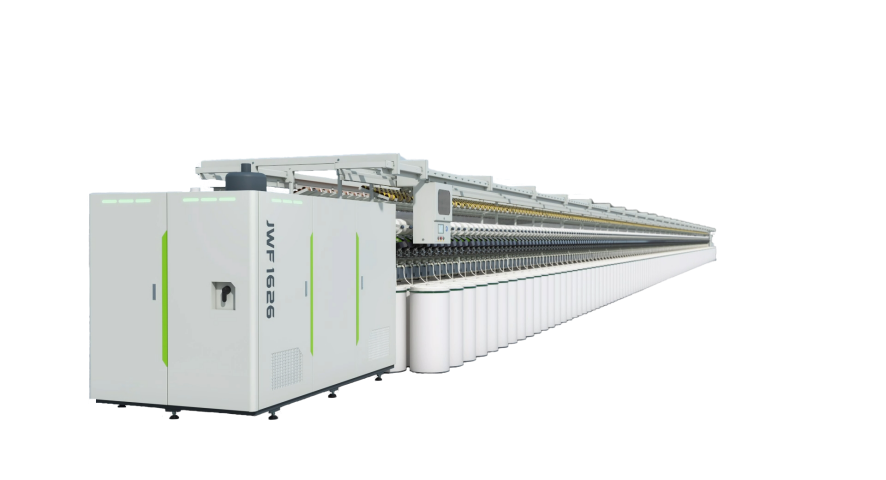

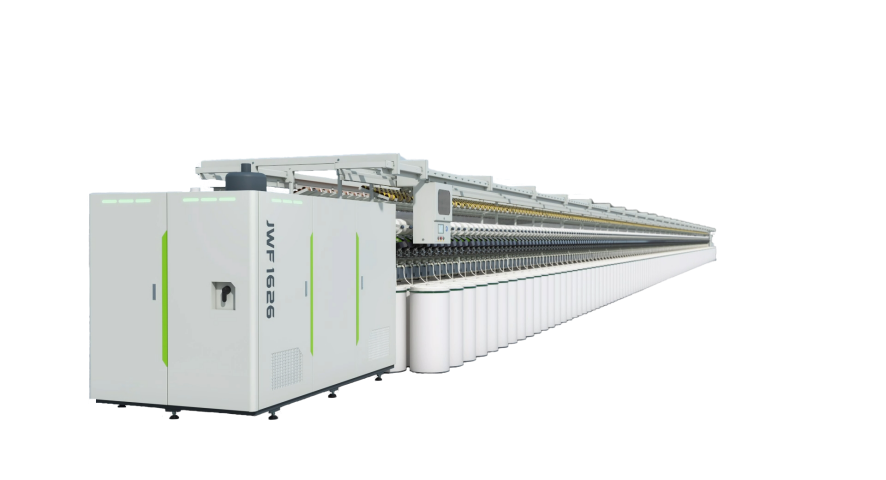

JWF1626 Fully Automatic Rotor Spinning Frame

The machine adopts high-speed suspension technology, the highest speed up to 150,000 rpm, and yarn speed is 300 m/min; single spindle automatic jointing, and the jointing success rate is more than 95%; its longest spinning units are 600, and 30 spindles can be automatically jointed at the same time; single spindle transmission allows stable and reliable operation; it motivated by digital technologies, and can be spun to different varieties of yarns at the same time; and its unique system reduces energy consumption by more than 10%.

VCRO PLUS-I Winder

The number of spindles is 6-72, with a winding speed of 400-2200 m/min. Negative pressure control and speed regulation are also included. Additionally, cylinder anti-folding is achieved throughout the process of controlling the motor speed. Tension control and electromagnetic pressurization are also present, with closed-loop control. It allows MESDAN air splicer, water splicer, and the newest electrical yarn cleaner of USTER and Loepfe. The accuracy of bobbin yarn can be controlled within 0.5%. In addition, there are these key features: flexible couplings, yarn quality traceability, automatic conveying of the entire process, and labor savings.

JWF1366 PRO Autoleveller Draw Frame

The design speed is 1200 m/min, and it is suitable for pure spinning and blending of cotton and cotton-type man-made fiber with fiber lengths between 20 and 120 millimeters. The dimensions of the feeding sliver can are diameter ≤1000mm, height ≤1400 mm, and the output of sliver can are diameter ≤600 mm, height ≤1200 mm, ≥900 mm. Key features include full-time automatic leveling, fully independent motor direct driving, multi-motor digital tension adjustment, high-efficiency cleaning system and self-cleaning cotton box, concave-convex rollers with compress lock , and optional cylinder structure.

JWF0018 Wide High-producing Sorter

The detection width is 1200mm/1600mm, the maximum output is 1600Kg/H, the overall power is 1.25kw, and the lighting is LED. The overall dimension (length x width x height) is 1100X2240X3300mm, and its main features are wide width, high yield, energy saving, AI technology, ultra-low cotton and remote operation and maintenance.