How is the start of the cotton textile enterprises in Jiangxi, Hunan and Jiangsu Nantong this year?

Mar 08, 2019 | by CT

[Jiangxi, Hunan]

Most of the enterprises visited by CCTA research group in Jiangxi and Hunan started construction around the eighth day of New year. Enterprises in Jiangxi are affected by the absence of some employees. At present, the ratio of machine start-up is about 70%. Enterprises in Hunan are mainly employed by local employees, and the employee arrival rate is good, with the ratio of machine start-up approaching 100%.

The enterprises visited by the research group mainly produce pure cotton yarn, a small amount of cotton blended yarn, mainly sold to Zhejiang, Guangdong and other places. The product inventory is mostly about half a month, and the raw material inventory is about one month. Enterprises said that the market is stable in the near future, and the company started in good condition in 2019.

In the survey, enterprises reflect that it is difficult for them to recruit workers, the older the employees are, the larger their mobility is. At present, the age of the employees interviewed by the research group is generally over 40 years old, and the recruitment is slightly difficult. Faced with this situation, most enterprises have the intention of equipment transformation, such as automatic yarn dropping, some enterprises have ordered new equipment, new plant is also under construction.

In addition, according to the enterprise introduction, Sino-US trade frictions mainly affect the confidence of downstream customers in the market. Enterprises that used to place large orders are afraid to place large orders at present, instead of small batches of orders, buy as needed. At the same time, Sino-US trade frictions have also affected the price of products. Enterprises said that since Sino-US trade frictions, the price of products has been unsatisfactory and the profits of enterprises have been compressed.

During the research group's visit, the enterprises expressed the hope that the country could further relax the quota policy to meet the needs of enterprises for cotton. Some enterprises in remote and poverty-stricken areas also said that the local electricity price was high and the transportation of raw materials and products was difficult. They hoped that the government would give more support to enterprises and support their development.

[Guangdong]

In Guangdong, the research group learned that the benefit of the region remained stable in 2018 compared with 2017. Sino-US trade friction had a greater impact on downstream clothing orders than on spinning orders, and had a greater impact on market psychology than on actual orders. In addition, the reform of the cotton quota system in 2018 is obvious, the publicity system improves the credibility of the government, and the domestic cotton gap will be solidified in the next few years. It is hoped that the country will make good use of the two major regulatory means of import and reserve to stabilize market prices, and production enterprises are most afraid of price fluctuations. Moreover, the pressure of recruitment after the festival is high, and the problem of difficulty in recruitment is becoming more and more prominent. The cities with less population inflow represented by Zhanjiang are mainly local workers, and the relative pressure is relatively low. The rate of rework after the festival is still acceptable. However, the monthly salary of workers is as high as 4500 yuan/month, the average age of employees is over 45 years, and the mobility of employees in some cities around Guangzhou is relatively high. It is understood that there are three main reasons for the difficulties faced by enterprises in recruiting workers: one is the decline in the number of workers brought about by the imbalance of population structure; the other is the change of employment concept; the glory of workers in the last century is no longer there; the young people's choice of jobs is more concerned with factors such as work comfort and environment; the third is the increasing convenience of transportation and the imbalance of regional development, which leads to the increase of population mobility. These deep factors are irreversible in the short run. In the increasingly obvious recruitment difficulties, upgrading and improving efficiency may be the only way out for textile enterprises.

[Nantong, Jiangsu]

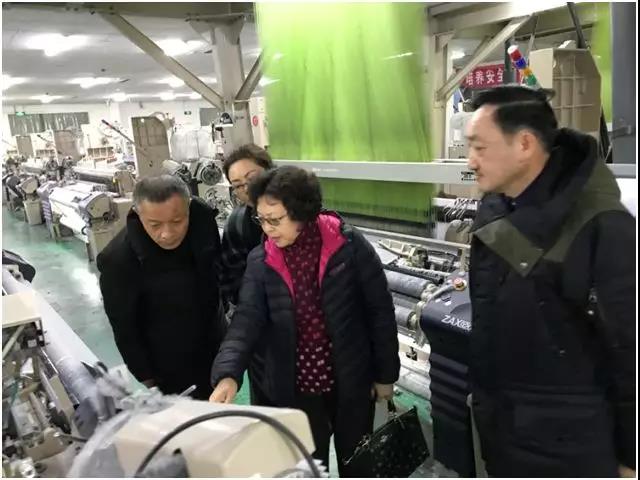

During the visit and investigation in Nantong, Jiangsu Province, China Cotton Textile Association visited the yarn-dyed fabric production enterprises and Jiangsu Dasheng Group Co., Ltd. together with the relevant leaders of Nantong Pioneer Street Office.

Nantong Pioneer Street, as China's cotton textile industry cluster area, adheres to the characteristics of the yarn-dyed fabric industry. It is understood that the start of 2019 is good, visiting enterprises have all started and basically full-load production, orders are relatively sufficient, some enterprises orders to May or June. The visiting enterprises are small in scale, with the number of looms ranging from 30 to 130. They pay attention to technological details and increase the added value of products, giving full play to the characteristics of small batch, multi-varieties and quick response.

In terms of transformation and upgrading, Jiangsu Dasheng Group Co., Ltd. is in the leading position in the cotton textile industry, and has a full-process intelligent spinning automation production workshop. Visiting yarn-dyed weaving enterprises to upgrade equipment and integrate cross-border with cultural creativity, some enterprises realized the importance of information construction in production management, and managed the data of products and crafts through modern means to save costs and improve efficiency.

According to enterprises, in terms of employment, more than 60% of local workers, employment is relatively stable. However, the rising cost of employment is one of the major challenges. The average salary of front-line workers in enterprises is more than 6000 per month.

In the aspect of green production, Pioneer Street owns sewage treatment plant, which centralizes the wastewater discharged by enterprises. From the point of view of green environmental protection and cost reduction, enterprises themselves take active measures to improve water reuse rate and reduce emissions. In addition, the visiting enterprises indicated that the pressure of tax and fee costs was great, and they hoped that the state could introduce relevant policies to further reduce the burden of enterprises.

The research team made a thorough discussion on the development of industrial cluster areas and relevant leaders of Pioneer Street. Both sides agreed that they should conform to the market development trend, strengthen the publicity of regional brands, give full play to the cluster effect, provide corresponding services and platforms according to the needs and wishes of enterprises, and jointly promote the high-quality development of local dyed fabric industry and enterprises.