Comprehensive quality assurance for nonwovens: USTER® Fabric Inspection for intensive production lines

Jan 15, 2020 | by CT

USTER provides premium solutions for the high-end nonwoven market. USTER’s expertise covers a wide range of textile applications from fiber to fabric and has a worldwide reputation. The current nonwovens industry has also witnessed and recognized the expertise and technical experience accumulated in the textile industry over the past 70 years. Expertise in yarn quality - including how to control all types of pollution - continues to provide quality assurance for fabrics and nonwovens today. This is based on the expertise of EVS, which was acquired by USTER Group in 2018 and is a global advanced high-tech supplier of automated visual inspection.

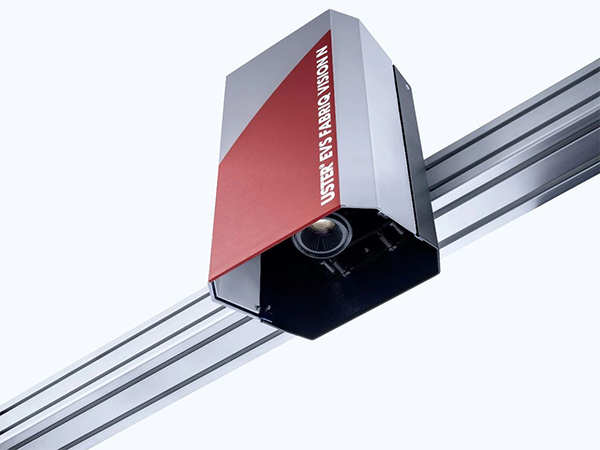

Now, the solution of USTER® EVS FABRIQ VISION N fabric detector can perfectly fit the production unit with tight space, at the same time ensure that the lighting conditions can achieve the best test results, and reliable data guarantee excellent quality output.

Manufacturers of automated online process control require a stable high defect detection efficiency to ensure reliable quality. The USTER® EVS FABRIQ VISION N fabric tester ensures reliable quality by using automated controls in the production process. The USTER® EVS FABRIQ VISION N fabric detector can objectively and consistently locate any visible defects. This system can locate and record the defects in each roll at the normal production line running speed.

“The USTER® EVS FABRIQ VISION N fabric tester is suitable for all applications, helping manufacturers significantly increase first-class output,” said John Belew, vice president of USTER Fabric Inspection. The system organically combines the complete fabric defect figure and the cutting optimization module to ensure that more first-class products are produced, and products with low quality are eliminated.